Brisbane Office – 0409 276 337

Townsville Office – 07 4774 6949

Safe Conveyor Systems in North Queensland

Environment, Health and Safety Policy

Britrac (Aus) Pty Ltd recognises and accepts that it has a legal and moral obligation to protect the health and safety of its employees, contractors engaged by the company and personnel working within or near our sites. Our safety philosophy is quite simple - reduce risk wherever possible by thinking about how work will be done before starting itself. This reduces risk to the lowest possible level. We make sure that staff members are sufficiently skilled and trained to work safely. Our policy ensures that the equipment and tools used and provided by us are safe to operate. We also check that our work environment is safe and tidy, and investigate incidents to prevent it from happening again.

All employees and contractors engaged by the company are expected to fulfil their obligations and responsibilities under relevant Occupational Health and Safety Legislation and our Safety Management System. As a service provider, we also recognise that our safety metrics has a direct impact on client's safety performance. With this in mind, we always endeavour to cooperate and work within the safety systems used by our clients. All our employees, including management, shall make themselves aware of our client's safety needs and abide by them.

Brian Steele

Managing Director

Britrac Australia Pty Ltd

Continuous Improvement Process (CIP)

As part of our service, we offer continuous improvement, which can be implemented to achieve the goal of longer lifetime, less downtime and more cost-savings for our customers.

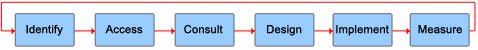

Our CIP is a six-step system:

This CIP comes at no extra cost to the client; however, if engineering design and drafting are required, we will pass on those costs. The process is basic, user-friendly and there are defined steps for each point. There is a sign off at each section, which ensures that everyone involved in the process understands and approves of the development.

Trialling of New Products

New products are always coming to the market, which claim to outlast and outperform their competitors. When considering new products or concepts, there is always a concern that realistic and accurate recording/monitoring has to be conducted. The client needs a system in place to control the trial and monitoring of its performance. This process ties into the concept of continuous improvement. Our system records and documents manufacturing dates, installation dates, expected life of the item and failure analysis. This information is then shared with relevant personnel and an evaluation report is completed.

Send us your requirements!

We will get back to you as soon as possible.

Please try again later.

For Conveyor Systems and Solutions that Adhere to Safety Standards

CONTACT

Email Us:

sales@britrac.com

ADDRESS

196 Enterprise St,

Bohle QLD 4818

1/24 Violet Street, Hemmant, QLD, 4174

AREAS SERVICED

We service North Queensland, Australia Wide and also supply and service Internationally.